Key Takeaways

- Petaluma Creamery successfully revitalized its cheesemaking operation by replacing manual, paper-based processes with Agentforce.

- By using generative AI for predictive order management, the creamery now accurately forecasts customer needs.

- AI-driven automation has allowed a single salesperson to reactivate former accounts and manage a growing revenue pipeline that previously would have required a much larger team.

A Jersey cow is a good cow. It is an inquisitive beast, and small (for a cow). Its eyes are dark and kind and alive. It produces less milk than the more common Holsteins, but the fat content is higher and the ROI and total cost of ownership work out pretty well. Larry Peter, a longtime dairy farmer, cheese maker, and recent Salesforce customer, put it this way: “I can feed three Jerseys for every two Holsteins. I get a 13% cheese yield with a Jersey, where a Holstein only has a 9 to 10% yield.”

Credit the cows for their innate efficiency, but credit some AI-enabled efficiencies established by Larry and his cousin Daniel for the recovery of the Petaluma Creamery, their cheese-making operation in Northern California. The creamery hit some hard times a while back and Larry even had to press pause on the business. But in the last two years, Larry and Daniel have infused the traditional practices of dairy farming with the optimization of cutting-edge enterprise technology to bring the creamery back to life.

“We were doing everything kind of old school before,” said Larry, “Now, we’ve been on Agentforce for more than a year. It tells us what accounts to go to on what day; it tells us who needs more cheese and what we need to deliver. It’s a really big support.”

Larry bought his first cow for $700 in 1986. That cow became a herd, which led to a cheese-making operation in a converted woodshed. Larry hired armies of salespeople to sell that cheese at more than 300 farmers markets across California and Arizona. Julia Child, who would meet him when he was in Santa Barbara, said his white cheddar was the best she ever ate.

The predictive order management system has enabled a single employee to connect with the stores that formerly carried Petaluma Creamery’s products.

In 2004, Larry bought the Petaluma Creamery, a much bigger operation. Within a year, he was bringing in a million pounds of milk a day and turning it into 100,000 pounds of cheese. He won gold medals at state fairs, and for a while he supplied product to 1,400 Chipotle locations.

But things took a turn: His overhead was too high to make the Chipotle account profitable; Covid hit hard; Larry had open-heart surgery; there were deaths in the family. Some maintenance in the plant was done poorly, which left Larry with huge bills. In September of 2022, he had to shut everything down. “I was lost, I didn’t know what I was going to do,” he said.

So he got in his car and went down to Silicon Valley to look for his cousin Daniel.

Bringing Salesforce Onboard

Larry had been wanting Daniel to come to work for him for a while. He knew that Daniel had been an applications engineer at Kenandy, an enterprise ERP platform founded by Sandra Kurtzig, one of Silicon Valley’s first female entrepreneurs. Larry also knew Daniel had done work with Del Monte — and that he was a Salesforce expert.

Indeed, Daniel is a 36x certified Salesforce MVP Hall of Fame member, which means he has passed three dozen different Salesforce certification exams. “I got to work with some of the original Salesforce engineers,” he said. “I got to sit in rooms with these legends, and things that I thought were going to take weeks to build, we’d build them in like an hour.”

Larry was nervous when he went down to talk to Daniel back in 2022. “I was sweating bullets. I didn’t know if he was really going to come and help me, and I didn’t have money to pay him,” said Larry. “But thank God, he wanted a change in life.”

Daniel, who agreed to become the CTO of Petaluma Creamery, likes to say that his whole career “was setting me up to do something like this.” Over the past two years, Daniel has helped Larry relaunch the creamery — not through more cows or better cheese, but lower overhead. “The creamery has to change to adapt to a new economic paradigm,” Daniel said. “It’s sort of like old school meets new school: If you want to do something cool like this and stay in business, you can’t afford to do it by having people do every step of the process.”

That’s where Salesforce comes in.

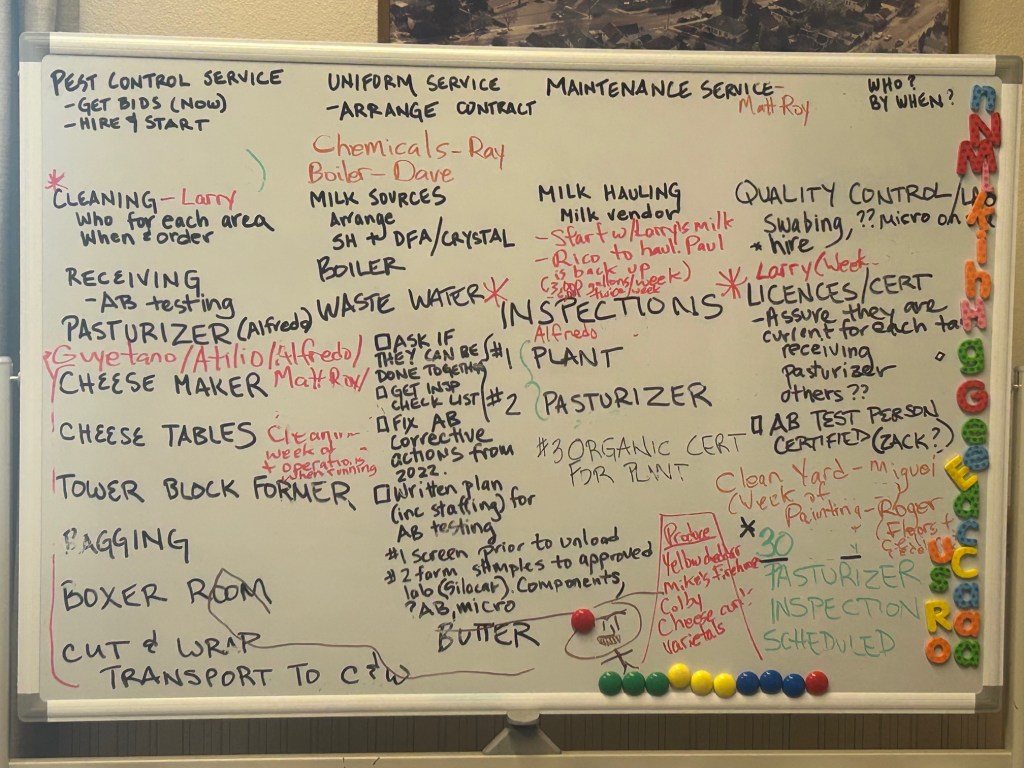

An easy example: The creamery used to take orders on paper and invoice them through QuickBooks. Now the creamery uses Agentforce Sales for its order-to-cash process.

It also uses Salesforce to track incoming milk, including the temperature, amount, and even the name of the driver transporting it; Agentforce helps them make use of the data.

Then there’s predictive order management, which uses generative AI to detect customers’ ordering patterns and propose new orders based on that data. The streamlined system has enabled a single employee to connect with the stores that formerly carried Petaluma Creamery’s products. Within the first six months, he worked through the top 1,000 of the 3,500 former customers and successfully reactivated more than one-third of them. He continues to cycle back through the remaining customers while also bringing in new ones. “The ROI is that we are building back our whole revenue pipeline with just one salesperson,” said Daniel. “To do something like that manually, you would need a lot more people.”

This level of automation and efficiency has been crucial to relaunching the business — which Larry credits Dan for saving. “What he can do in 30 minutes, I couldn’t do in days,” Larry says. And Dan says he’ll be even more efficient as vibe coding — with tools like Agentforce Vibes — becomes more powerful. “People use gen AI to write emails, to write contracts. Code is just another kind of document, and generative AI is going to consume that task too,” he said.

Using AI to Prospect Leads

You cannot, however, vibe code cheese. It’s made on the creamery manufacturing floor, where the milk comes in and cheese and butter and ice cream come out. Pipes and tubes snake everywhere.

In the warehouse, boxes of salted butter, Monterey Jack, cheddar and other varieties sit on racks ready to ship. The warehouse isn’t particularly full right now: the cheese is going out faster than it’s coming in, which is a good sign.

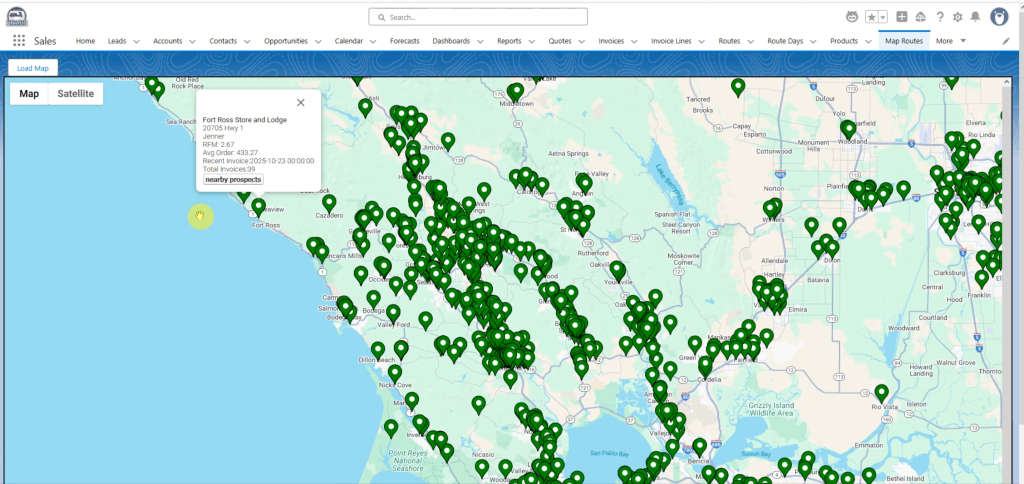

That success is partially because of another clever Salesforce implementation. He used the Google Places API to input every grocery store, restaurant, and convenience store in California into Salesforce as a potential lead. If a delivery person or sales rep visits a particular store near Fort Ross, for example, they can see likely new customers on a map and call on them with some samples.

“I’m a salesperson driving to a store to deliver cheese,” Daniel explains. “I’d like to visit other locations in the area which aren’t customers to try to sell them cheese also. Here is the latitude and longitude of the store I’m going to. Given the list below of other places in the area, pick out 10 which appear to be restaurants, delis, cafes, or kitchens which are closest in latitude and longitude to the store I’m visiting. Include the street and city in the list. First prioritize the ones that are closest, then prioritize the ones that are the highest price level, review rating, and number of reviews.”

The combination of art and science – of artisanal quality and technological deployment – is helping bring Petaluma Creamery back to life. Larry chokes up a little bit when he talks about it. “Salesforce makes me know that I’m going to own my pillow again; I’m going to have a good night’s sleep. And it makes me know that I’m going to be successful with everything that I’ve worked for. It’s all about putting out the best product you can, and it’s all about the integrity of what you do in your life.”

Giving Small Businesses a Chance

Keeping a family business open is hard. And reimagining that business for the modern era can be hard, too. Larry’s advice is to get help. “Don’t think you can do it on your own. Ask for help. Call Salesforce. Call people that know the programs.” He has gone from nothing to $300,000 in revenue in the last few months, and expects to be at $10 million within a year.

Neither Larry nor Daniel believe it’s possible to scale a small business without this kind of AI assist. They don’t think it’s feasible to have people do every step of the process any more. Which, in a lot of ways, is an opportunity. The internet has put a lot of mom and pop stores out of business, notes Daniel. “Now small businesses have the same technology that the big companies have. People still want local things. AI gives them a chance to keep their costs down enough to keep making these cool, unique products, and do it in a way where they can be profitable.”

The Jerseys in the field don’t care about profit, or AI. They care about eating the bright green grass – so bright on a December morning that it looks backlit. Thanks to Larry and Daniel’s efforts, they’ll be able to keep eating it for a nice long time.

Go deeper:

- Discover how this Texas boomtown used AI to reinvent city government

- Think big, start small, scale fast: customer learnings on AI deployments

- For these companies, always-on AI is a matter of course