Despite trade uncertainty and tariff challenges, India’s manufacturing sector has plenty to be optimistic about. Strong policy reforms and incentives, as well as rising domestic demand, are unlocking new opportunities for growth in an industry that already accounts for 17% of India’s GDP.

But as manufacturing momentum builds, the competition from global players is heating up. Customer expectations and operational complexities are also on the rise. What then will it take for Indian manufacturers to succeed and differentiate themselves on the world stage?

The answer may very well lie in something many manufacturers already have, but haven’t fully tapped: data.

The shift from product-centric to data-centric manufacturing

Indian manufacturers have spent decades perfecting the mechanics of production. They’ve streamlined assembly lines, automated shop floor operations, and optimised supply chains. The goal? To boost operational efficiency – i.e, maximise output in the shortest time with the fewest resources.

But in today’s ‘age of the customer’, success is achieved when operational efficiency goes hand-in-hand with customer satisfaction. The more a manufacturer knows about what customers need and when, the better they can engage and serve their customers, driving satisfaction and repeat business.

This has made customer data a key competitive differentiator. When properly harnessed, customer data doesn’t just provide powerful insights on how customers engage, or which products they prefer – it also pinpoints untapped revenue opportunities, signals cross-sell and upsell potential, and surfaces emerging market trends before they become obvious.

Product and asset data complete the picture, providing vital context on equipment usage patterns, service history, warranty coverage, and other details.

Bring these data sets together, and a number of possibilities emerge. Let’s say an industrial pump manufacturer captures sensor readings that show a unit heating up more than normal. This data is then cross-referenced with customer data indicating round-the-clock summer operations. Product wear-and-tear patterns are also factored in. The manufacturer can now predict the likelihood of a component failure, and proactively schedule a seal replacement – so, the customer’s operations remain uninterrupted.

B2C manufacturers are leading the way in data management by establishing channels to gather and integrate real-time customer feedback into service, operations, and quality control. Even B2B manufacturers – most of whom have traditionally relied on stable, long-term customer relationships – are recognising the importance of a data-driven approach.

Unlock value from fragmented data

The challenge for Indian manufacturers isn’t a lack of data. Factories, warehouses, supply chains, and customer engagement channels generate vast volumes of data every day. But this data remains scattered across a maze of legacy systems and point solutions that don’t talk to each other.

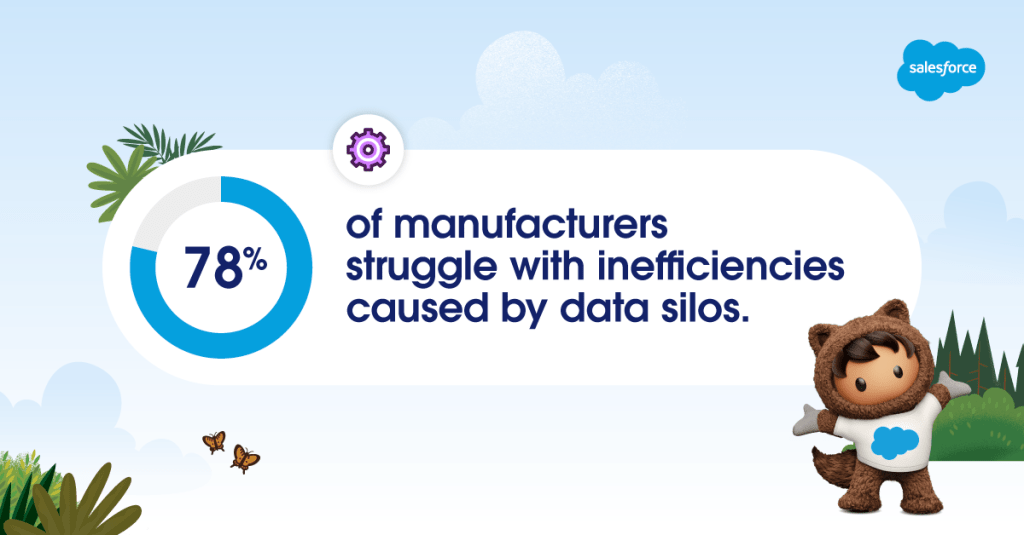

Many manufacturers have multiple ERPs, never mind other platforms. And with additional tools being integrated through acquisitions, it’s no surprise that 78% of the manufacturers surveyed in our global Trends in Manufacturing report say they spend a substantial amount of time looking for information across systems.

But a better way exists. By unifying data on a single platform – like Salesforce Manufacturing Cloud – manufacturers can gain a connected, 360-degree view of customers, products, and assets across the value chain. This data can then be used by multiple teams and functions to personalise customer interactions and communications, reduce service response time, and unlock new revenue streams. Tata Power Solaroof proves how powerful such an approach can be. With Salesforce, the solar panel manufacturer has built a single source of truth to capture, qualify, and follow up on leads. The entire sales process is now managed on one platform, speeding up response time, while optimising lead conversion rates. The result? A 200% surge in residential solar installations.

Turn data into insights with AI and analytics

Once data is unified, it’s time to transform it into action. Analytics can dig deep into the data to reveal powerful insights – such as where operational productivity is lagging, or where revenue is trending.

AI can go even further. Data provides the foundation on which AI learns to recognise patterns, extract meaningful intelligence, and make informed predictions. But for AI’s outputs to be reliable, the data first has to be clean, accurate, and comprehensive. That means scrubbing out duplicates and errors, while also structuring and standardising the data.

When the data is organised, AI can be put to work. Agentic AI like Agentforce empowers manufacturers with trusted AI agents that not only automate processes at scale – they also turn raw data into rich insights that help improve both customer satisfaction and production.

Here are 5 ways manufacturers can use agentic AI:

- Prevent asset downtime: AI agents can analyse equipment service history and telemetry data to predict potential failures. Manufacturers can then proactively schedule maintenance, minimising unplanned downtime.

- Improve customer service: By analysing and summarising customer interactions, AI agents can help service reps provide better, faster customer support.

- Personalise product service campaigns: Agentic AI can harness customer data and purchasing history to create targeted campaigns that connect the right products and services to the right audiences at the right time.

- Strengthen sales agreements: With AI agents, manufactures can automatically identify discrepancies and inconsistencies in sales agreements. This helps cultivate trusted relationships with customers and suppliers.

- Optimise inventory levels: AI agents can monitor inventory, analyse sales, and forecast demand to ensure that stock is always available when customers need it. Additionally, the agents can identify patterns and trends in consumer behaviour, allowing manufacturers to adjust their production and inventory strategies accordingly.

Looking ahead

With every leap in AI, the possibilities for customer satisfaction and innovation expand. But a lot will depend on how well manufacturers harness data.

Ready to learn how you can transform your data into actionable, powerful insights?

We’ve put together The Indian Manufacturer’s Guide: Translate Data into Intelligent Insights and Actions to help you get started. Filled with real-world stories and practical takeaways, this ebook dives into how Indian manufacturers like you can leverage data as a competitive differentiator and growth driver using AI, automation, and analytics.

Unlock Growth with Data-Driven Manufacturing

Learn how to establish a data-centric approach to drive efficiency, and get a unified view of your manufacturing operations.